HDD Ultra Compact Servo Motors

Compact Design and High Reliability.

The ultra compact design save weight and space without reducing the high torque. Very high reliability and quality gives the application a low total cost of ownership. Our servo motors are delivered in different types and can be integrated with any servo system on the market.

Our innovative and unique stator design enables us to combine high torque with a very compact design into the most efficient and dynamic PMS servomotor on the market. The technology means that our motors are up to half the size of our best competitor. The modular design concept enables us to manufacture a number of varied sizes and models such as Solid shaft, Internal coupling and Hollow shaft servo motors. We also have a large number of feedback with encoders which means you can integrate our servo motors to most types of servo drives and easily adapt our design to several types of connectors. Combined with our high engineering skill our flexible design concept enable us to customize a servo motor to any specific customer need.

Compact motors

Solid Shaft Motors

The HDD Solid Shaft Motor is our most sold motor. The motors are available in 92 – and 140 mm frame sizes, in a torque range from 1.2 Nm to 10 Nm, rated 3000 or 6000 rpm and wound for 230 or 400 VAC. All motors can be supplied with or without brake.

The standard motor is equipped with keyway, straight connectors, resolver feedback, PTC thermal sensor and IP-65 protected.

Compact motors

Hollow Shaft Motors

The HSM Hollow Shaft Motors have the same excellent power and torque density properties as the solid shaft servo motors, but with a hollow shaft. It allows for example axles, cables, liquids or laser beams to be passed through the motor. The 45 mm hollow shaft has a thru center hole of 30 mm (40 mm on request). The motors are available in a torque range from 2.6 Nm to 4.8 Nm, rated 3000 rpm and wound for 230 or 400 VAC.

Compact Motors

Internal Coupling

The technology with integrated coupling, enables even more compact installation of servo motors. The technology with integrated metal bellow coupling, enables even more compact installation of HDD motors.

The motors are available in 92 – and 140 mm frame sizes, in a torque range from 2.3 Nm to 10 Nm, rated 3000 rpm and wound for 230 or 400 VAC. All motors can be supplied with or without brake.

Compact motors

Low Voltage Servo

The HDD low voltage servomotors are built with the same technology as our traditional AC servomotors. However, they have a coarser winding to cope the higher currents when controlled by a low voltage servo drive.

Low Voltage is available for Internal Coupling, Hollow Shaft and Solid Shaft servo motor series

Special motors

Open Frame Servo

HDD offers open frame or frameless motors for direct integration in your application. Integrating the stator direct into your housing reduces size and weight. It is ideal for machine designs that require high performance in even smaller spaces than possible with HDD’s compact motors.

SPECIAL motors

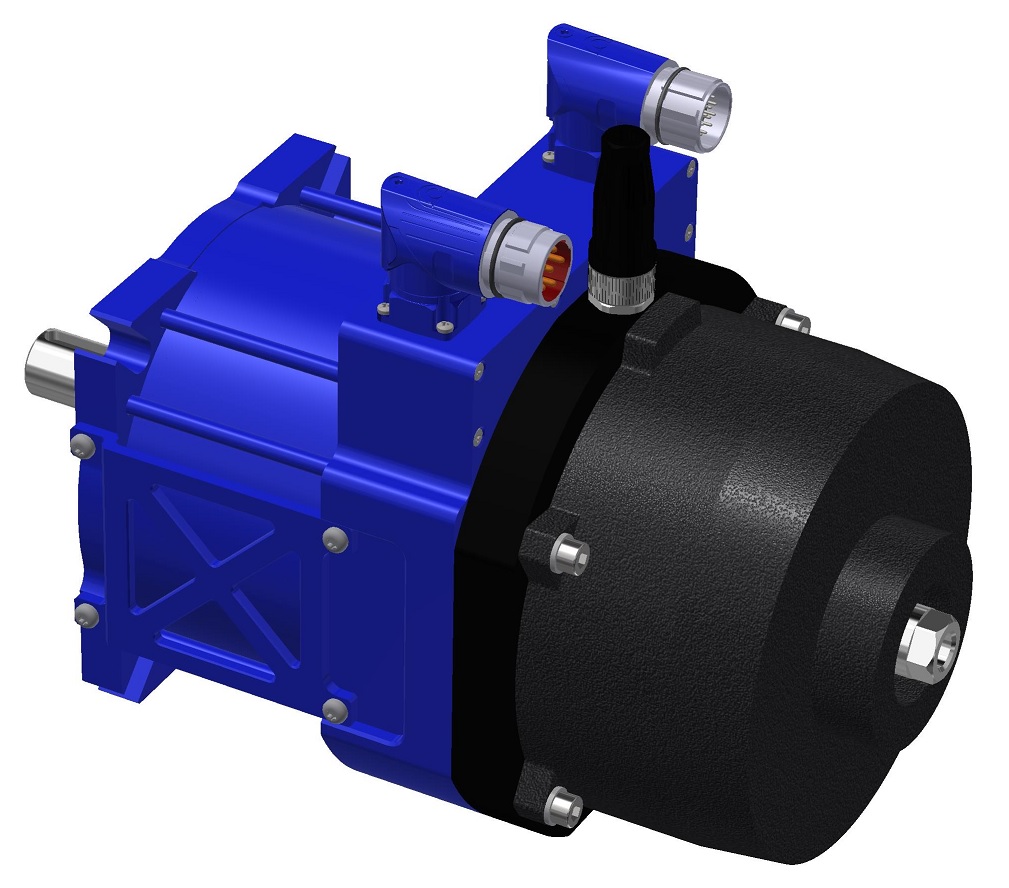

Ballscrew Servo

HDD’s ball screw servo motor transforms the motor axel rotation to an axial movement. The ball screw servo motor is designed to directly drive a spindle nut. By integrating the ball screw in the centre hole of the motor shaft you can receive a compact direct driven solution for axial movements.

Special motors

Custom Servo

HDD innovative stator design and highly skilled design team creates a unique ability to customize standard motors to specific needs and with a cost-effective production even in small volumes. A custom servo motor allows clients to create a competitive advantage. HDD has developed several methods for cooling the motor, thus increase performance as well as modifying the connectors, shafts and mounting. Custom servo motors in any shape, size or form.

HDD’s servo motors work with any servo drives

A servo motor allows for precise control of angular position. It consists of a motor coupled to a sensor for position feedback. It also requires a servo drive to complete the system. The drive uses the feedback sensor to precisely control the rotary position of the motor.

HDD’s portfolio of servo motors gives you flexibility so you can select the best servo motor for your application. You can integrate our servo motors with any servo drives, to create the best solution for you. HDD’s different servo motors enable a unique possibility to optimize your solution to your specific needs. You can work with our engineering team to customize a solution.

In-house manufacturing and own production chain

Customised advanced solutions from skilled engineers

Cost effective products by modular design

Customer oriented with flexible approach

Innovative servo motion engineering since 1994

Customized Servo Motors

Customized

High Speed Wire Feeding

- Wire feeding start and stop 40 times per second

- Exact feeding 30 or 32 mm wire feeding

- ICM servomotor for compact design

- Extreme requirements of reliability

- High quality of servo motor with long lifetime

- Integrated with B&R controls

Customized

Motor with special brake

- Compact motor with external brake supplied by customer that fulfils EN 14492-2, hoist classification.

- Customized motor manufactured in small volumes

- Extreme requirements of reliability

- High quality of servo motor with long lifetime

Customized

Tool Spindle Servo Motor

- Hollow shaft, for dust extraction, 6000 rpm

- Compact, dynamic and capable of high peak torques.

- Heavy Duty – reinforced bearings to handle high radial and axial loads.

- 100 x 100 mm frame size

- Customized motor manufactured in small volumes

- Extreme requirements of reliability

- High quality of servo motor with long lifetime

Custom & Customized Servo MotOR Client Cases

How we helped clients with their servo motion challenges

AV&R’s TF-X 1200 robotic system chooses high-speed and ultra-compact HDT09J

AV&R in Quebec, Canada, is a manufacturer of robotic systems for surface finishing and visual inspection of manufacturing parts of different sizes, whether cast or forged.

HDD14N for hoist application

Customized HDD14N for hoist application with resolver and external brake supplied by the customer. The brake fulfils EN 14492-2, hoist classification. The rear housing is adapted to fit the external brake and coarser bearings are used to withstand the extra load In the event of a power failure,

DDD-Diagnostic Trusts HDD for Critical Gamma Camera Applications

Industry: Nuclear Medicine Location: Copenhagen, Denmark Product: HDD Solid Shaft Servomotors DDD-Diagnostic (X3D) Trusts HDD for Critical Gamma Camera Applications DDD-Diagnostic A/S, located in Copenhagen, Denmark, is a world leader in the design and development of...

HDD tool spindle servo motor

The HDD tool spindle servo motor is based on our HDT09N motor with rated torque 3.6 Nm at rated speed 6 000 rpm. The motor is compact, dynamic, and capable of high peak torques. It has reinforced bearings to handle high radial and axial loads.

Let’s Talk

Get help from our skilled engineers

We often help our clients to solve their advanced motion challenges. Our expertise span is very wide and we always take your needs and questions seriously.