In the world of precision engineering, space and weight are crucial considerations. HDD Sweden AB has long been at the forefront of innovation with its ultra-compact servo motors.

HDD Internal Coupling Servo Motor

This revolutionary motor integrates a high-performance bellows coupling directly into its design, further reducing the need for additional components and streamlining engineering solutions.

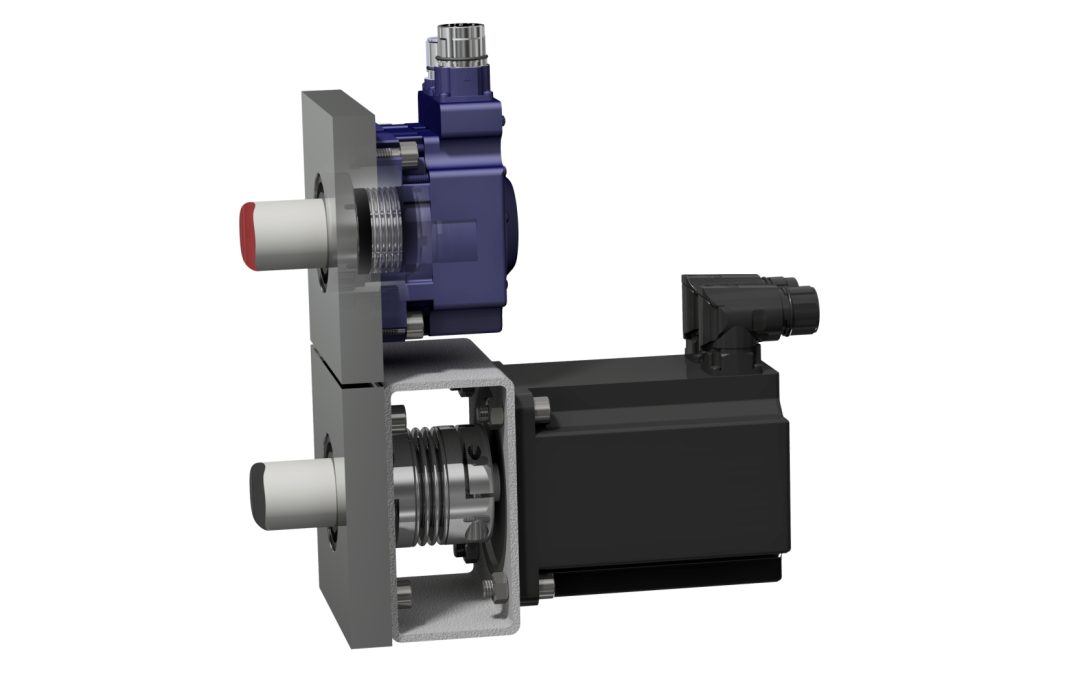

By integrating the bellow coupling inside the rotor shaft the design length can be reduced by up to 65 % compared with traditional solid shaft technology. The integrated coupling solution combines high performance servomotor solution with very compact design and low weight which gives a competitive advantage when designing complex automation solutions.

Integrated Metal Bellow Coupling for Space and Weight Optimization

HDD’s internal coupling servo motor builds upon the compact design philosophy for which the company is known. The motor is already up to half the size of competitor alternatives, saving both space and weight in engineering designs. This “integrated coupling motor” provides engineers with an even more compact and efficient solution.

Integrated bellow coupling

The image above shows a comparison of a HDD integrated bellow coupling motor and a reference motor having equal performance and a traditional shaft coupling solution.

A Game Changer Where Precision is Critical

Bellows couplings are widely recognized for their high torsional stiffness, which allows them to transmit torque without twisting or distorting. This makes them particularly suitable for applications where precision is critical. The bellows coupling in HDD’s servo motor is designed to handle misalignments, both axial and angular. They accommodate runouts of 0.2 and 0.3 mm respectively and have a stiffness of approx. 9 kNm/rad.

Instead of using an external connector between the motor and the shaft, the metal bellows coupling allows for direct fixation. The motor’s unique design saves significant space, making it ideal for applications where every millimeter counts. With one simple motion, the bellows coupling can be attached to the motor, allowing for seamless integration and quick installation.

Applications in Diverse Industries

HDD’s internal coupling servo motor, with its integrated bellows coupling, is poised to become a game-changer in various industries. From machine tools and manufacturing machines that require precise positioning, to robotics or 3D-printers where smooth and accurate movement is essential.

If durability and performance are critical criteria’s this motor offers versatility and reliability. The integrated coupling motor not only simplifies the design but also enhances performance across these applications.

Optional Brake for Added Control

All HDD internal coupling motors are available with or without an integrated holding brake, allowing for even greater control and flexibility in a variety of operating conditions.

The bellow coupling is axially attached to the rotor shaft for a smooth and robust joint.

Installation example.

HDD Sweden – Innovative Motion Engineering Since 1994

This unique coupling solution from HDD Sweden AB is a prime example of how the company continues to push the boundaries of what’s possible in servo motor technology. Engineers looking to optimize their designs for space, precision, and efficiency will find an invaluable tool in HDD’s internal coupling servo motor.

Read more, download pdf & CAD-files of HDD Internal Coupling Motors