A servo motor is an electric motor used to rotate or move an object with high precision. Unlike a traditional electric motor, which simply spins when powered, a servo motor is designed to control position, speed and acceleration. This is done through feedback where a sensor in the motor tells the control system to adjust the position of the motor shaft to achieve a precise placement.

A servo system usually consists of:

- The motor that generates the movement.

- A control unit (servo drive / servo amplifier) that gives orders about how the motor should move.

- A sensor (encoder / encoder) that feedbacks the position of the motor shaft.

Areas of use for servo motors

Servo motors are used where precise movement and positioning is required. Common applications include:

- CNC machines – for precision machining.

- Automation – in production lines where precise and repetitive movements are required.

- Industrial robots – for precise handling and placement of objects.

- Medical equipment – e.g. surgical robots and scanning equipment.

- Additional applications – such as drones, camera stabilizers, and other high-precision systems.

Important parameters for dimensioning and selecting a servo motor

- Torque: The amount of power that the engine needs to deliver for the operating case.

- Speed (rpm): The speed required for the given application. Nominal speed or maximum speed.

- Accuracy (Precision): How precisely the servo motor can position an object or maintain a defined speed.

- Physical size of the motor: It is often beneficial for the motor to be as small and light as possible for the given operating case.

What does AC and DC mean for servo motors?

AC and DC are different types of electrical current used to drive servo motors.

- AC = Alternating Current (Alternating Current)

- DC = Direct Current (Direct Current)

Depending on the type of current the servo motor uses, they are divided into AC servo motors and DC servo motors, and they work a little differently.

AC servo motors

An AC servo motor is powered by alternating current. These motors are common in industrial applications due to their durability and ability to operate efficiently at higher loads. They are brushless, which means they have fewer wearing parts and therefore longer life and require less maintenance.

Advantages of AC servo motors:

- High performance: Can handle higher loads and speeds.

- Durability: Less maintenance and longer life.

- Stable operation: Suitable for continuous operation and applications that require high precision over time.

Areas of use:

- Industrial machines

- Robotics

- CNC machines

Low voltage applications

An AC servo motor system can also be operated with DC. For these applications, servo drives designed for direct current are used that convert DC to AC in order to drive the motor.

This is common for, for example, AGVs and other battery-powered vehicles, where grid connection is not possible.

These AC motors have thicker windings to handle the higher currents generated when controlled by a low voltage servo drive. They are sometimes, somewhat incorrectly, called DC servo motors when in fact they are AC motors driven by a DC voltage source.

DC servo motors

A DC servo motor is powered by direct current, where the current flows in a single direction. DC servo motors are often brushed motors, meaning they use carbon brushes to transfer current to the rotor. This makes them easier and cheaper, but the brushes wear out over time and require maintenance.

DC servo motors are an old technology rarely used in modern applications.

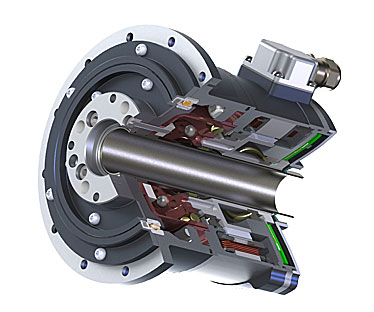

How is a servo system structured?

(Image of motor, servo drive and cables (if PLC) with descriptive text on the components. )

- Servo motor

- Feedback in the motor (feedback sensor)

- Servo drive

- Cables

- PLC with I/O

Why choose HDD as a servo motor supplier?

HDD manufactures ultra-compact servo motors, i.e. they deliver high torque in relation to the size of the motor. Our servomotors are available in a variety of designs and can be integrated into all servo systems on the market. We are used to manufacturing specially adapted engines in small series

We are flexible and strive to always give quick answers. We enjoy discussing complex automation challenges and can help with innovative ideas.