Ultra Compact Servo Motors & Excellent Engineering Support

Swedish Ultra Compact Servo Motor Solutions with Outstanding Performance and Quality

HDD Internal Coupling Servo Motor Revolutionizing Engineering Design

In the world of precision engineering, space and weight are crucial considerations. HDD Sweden AB...

Ultra Compact Servo Motors

Servo Motors With Superior Power-to-Size Ratio All HDD Servo Motors feature an ultra-compact design, high reliability, and a superior power-to-size ratio. Thanks to our...

Compact Motors

Our innovative and unique stator design enables us to combine high torque with a very compact design into the most efficient and dynamic PMS servomotor on the market. The technology means that our industrial servo motors are up to half the size of our best competitor.

Special Motors

HDD innovative stator and modular design system combined with a highly skilled design team creates a unique ability to customize our industrial servo motors to specific needs and with a cost-effective production even in small volumes.

Solid Shaft Motors

HDD Solid Shaft is our most sold servo motor. Available in a torque range from 1.2 Nm to 10 Nm, rated 3000 or 6000 rpm and wound for 230 or 400 VAC. The motor is equipped with keyway, straight connectors, resolver feedback, PTC thermal sensor and IP-65 protected and can be supplied with a brake.

Hollow Shaft Motors

The Hollow Shaft Motors have the same excellent power and torque density properties as the solid shaft servo motors, but with a hollow shaft.

Internal Coupling Motors

The unique HDD technology with an integrated bellow coupling, enables a more compact installation of servo motors.

Low Voltage Motors

Servo motors controlled by a low voltage driver. Low Voltage is available for our Solid shaft, Hollow Shaft and Internal Coupling Motors.

Open Frame Motors

HDD offers open frame or frameless motors for direct integratin in your application. Integrating the stator direct into your housing reduces size and weight.

Ball Screw Motors

DD’s ball screw servo motor transforms the motor axel rotation to an axial movement. The ball screw servo motor is designed to directly drive a spindle nut.

Custom Servo Motors

A customized servomotor allows our customers to create a competitive advantage for their products.

What you can design we can build

With a deep knowledge and a service minded and flexible approach we help clients solve advanced motion challenges!

Special Motors

HDD innovative stator design and highly skilled design team creates a unique ability to customize standard motors to specific needs and with a cost-effective production even in small volumes.

Open Frame Motors

HDD offers open frame or frameless motors for direct integratin in your application. Integrating the stator direct into your housing reduces size and weight.

Ball Screw Motors

HDD’s ball screw servo motor transforms motor axel rotation to axial movement. The ball screw servo motor is designed to drive a spindle nut.

Custom Servo Motors

Custom and customized servomotor allows our customers to create a competitive advantage.

What you can design we can build!

With a deep knowledge and a service minded and flexible approach we help clients solve advanced motion challenges!

In-house manufacturing

Highly skilled engineers

Customized advanced solutions

Customer centric

Cost effective by modular design

Servo motion engineering since 1994

Custom & Customized Servo MotOR Client Cases How we helped clients with their servo motion challenges

Customized hollow shaft motor based on HSM09-series

Customized hollow shaft motor based on HSM09-series Custom motor…

Read More

AV&R’s TF-X 1200 robotic system chooses high-speed and ultra-compact HDT09J

AV&R in Quebec, Canada, is a manufacturer of robotic systems for…

Read More

HDD14N for hoist application

Customized HDD14N for hoist application with resolver and external…

Read More

DDD-Diagnostic Trusts HDD for Critical Gamma Camera Applications

Industry: Nuclear Medicine Location: Copenhagen, Denmark Product:…

Read More

ENGINEERING SERVICES

DO YOU HAVE A SERVO MOTION CHALLENGE?

We have a flexible approach and give fast answers. We enjoy complicated automation challenges and support you with innovative ideas.

Get access to our highly skilled engineers with broad experience from different industries by reaching out.

Customized Servo Motors

Customized hollow shaft motor based on HSM09-series

Customized hollow shaft motor based on HSM09-series Custom rotor shaft with splines for direct fitting to the customers gearbox transmission. Custom front shield for direct attachment to the customers gearbox housing...

Read More

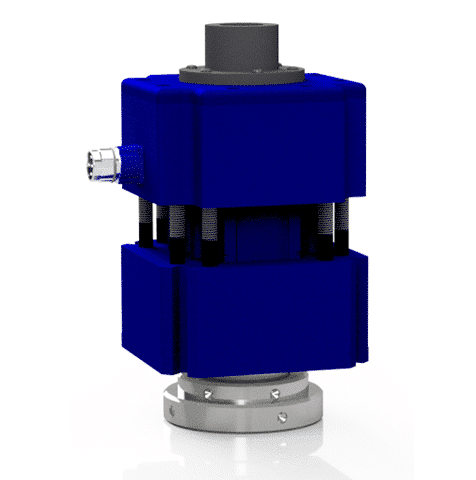

HDD tool spindle servo motor

The HDD tool spindle servo motor is based on our HDT09N motor with rated torque 3.6 Nm at rated speed 6 000 rpm. The motor is compact, dynamic and capable of high peak torques. It has reinforced bearings to handle high radial and axial loads. HDD specialize in special…

Read More

Husqvarna Professional Concrete Tools

HDD has helped Husqvarna Construction Equipment launch the Prime series, converting previously hydraulic tools to electric drive. The reduction in weight means that what used to be a two-man job can now be done by just one man and this reduces the cost of construction…